Systems audits are conducted to assess the suitability of the processes that maintain the structural integrity, safety, and reliability of machines such as shiploaders, stackers and reclaimers.

They are intended to be a holistic and comprehensive review of:

- Systems critical to the structural integrity of a machine (such as condition inspection regimes and critical protection systems).

- Regulatory compliance of the machine.

- Change management processes for critical systems.

- Machine operating parameters and alarm/trip parameters (i.e. check that the machine is operating within its design envelope).

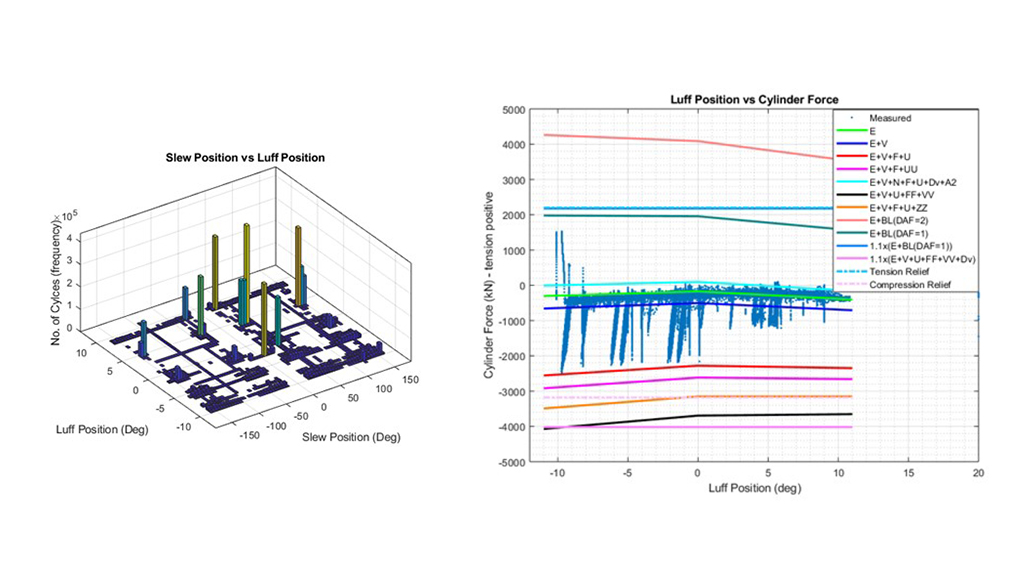

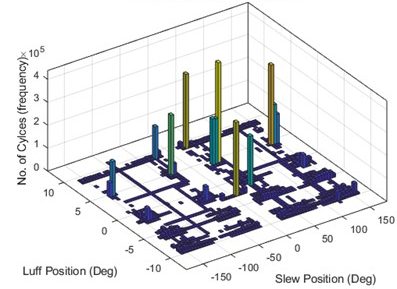

A systems audit includes a high-level inspection of the physical condition of the machine and its safety systems. The findings can be compared against previous inspection findings to determine the effectiveness of the existing structural integrity inspection regime. If available, a review of operational data (SCADA* data) and protection systems settings is conducted to check that critical operational limits and safety systems are working as intended. The figures below show some of the output from a SCADA data review of a machine, and a comparison to AS4324.1 load cases.

Interviews with maintenance personnel and maintenance documentation reviews are also conducted. This presents clients with the opportunity to review maintenance procedures, which may not have been changed since commissioning, and assess the relevance against current best practice. The audits also allow a comparison of the actual machine condition against the client’s perceived condition.

Up to date maintenance and protection systems are pivotal in ensuring assets meet the intended design life. ASPEC recommends conducting systems audits every 4-6 years.

Luff Angle vs Slew Angle

Luff Angle vs Slew Angle

Operating Luff Cylinder Force VS Design Cylinder Force

Operating Luff Cylinder Force VS Design Cylinder Force

*SCADA = Supervisory Control and Data Acquisition

Ashvin is a Mechanical Engineer at Aspec Engineering with 3 years’ experience. He has been involved in a variety of projects within the minerals and metals industry such as coal, iron ore and bauxite.