Car dumper replacements are strategic investments that extend the life of bulk handling operations. ASPEC’s recent study not only outlines potential costs and operational adjustments but also examines the downtime associated with each replacement strategy. This provides valuable insights for other facilities planning similar upgrades.

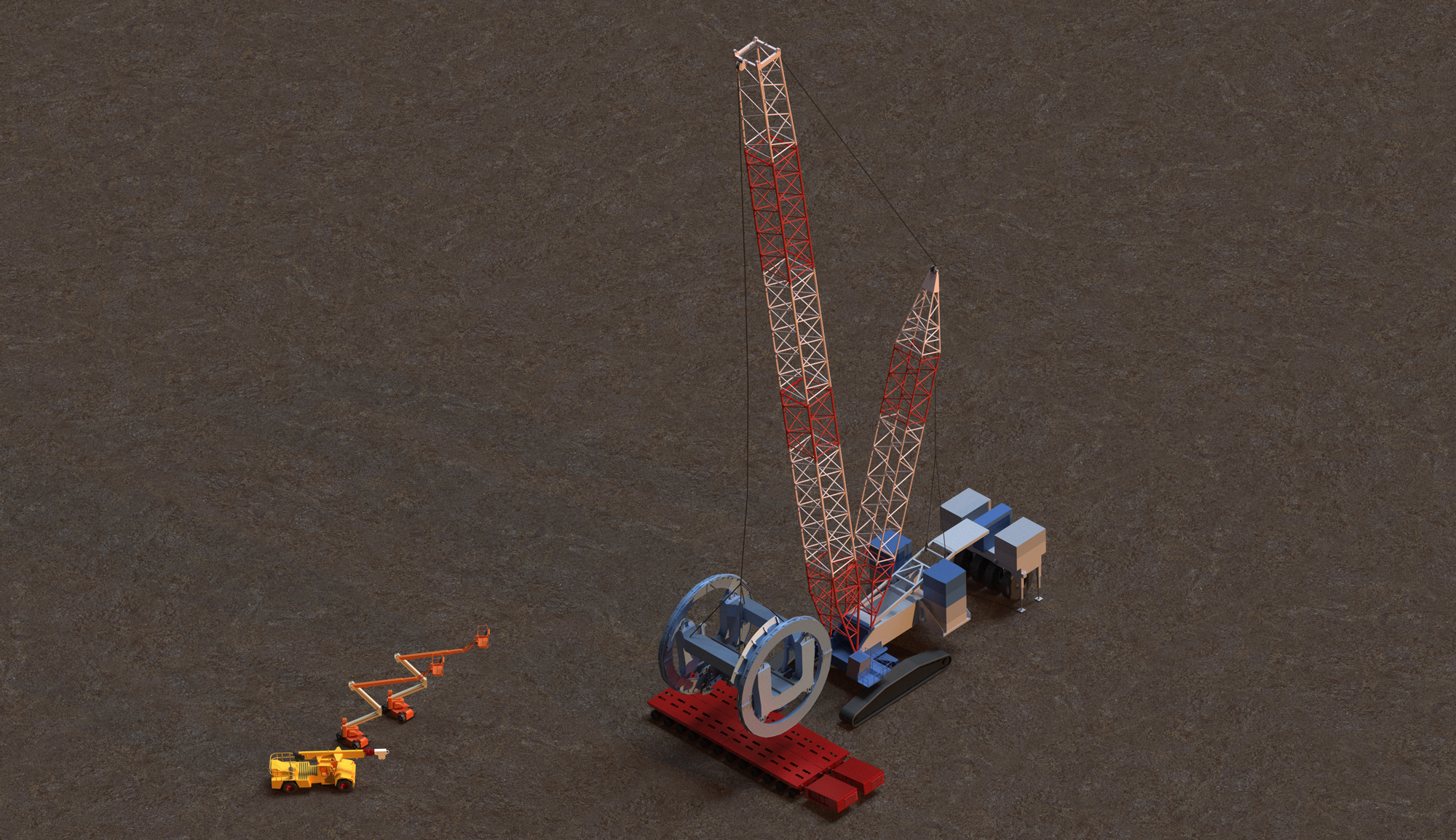

ASPEC carried out a combined Order-of-magnitude/Pre-feasibility study for the replacement of an ageing twin cell car dumper. The client was operating a number of other car dumpers with the same design so the study findings were to be used in the development of a program to change out the other car dumpers as they approached the end of their design lives. The study had to consider a host of factors for determining the best option to carry forward:

- Future operating changes such as an increasingly wet ore (causing higher dumping loads) and the potential introduction of Battery Electric Locomotives.

- Costs associated with ongoing crack/corrosion repairs, in-situ refurbishment, like-for-like replacement and replacement with an upgraded design (necessitating changes to the car dumper facility).

- Shutdown durations associated with the various strategies for maintaining the availability of the car dumper.

The study used Multi-criteria analysis to identify the best option to carry forward.

Matt Rudas is a Chartered Professional Engineer with over 25 years of mechanical and structural engineering experience. He has both Masters and Doctorate degrees in the numerical modelling of fracture and crack growth problems. Matt’s expertise is in mechanical/structural design, fracture, fatigue and dynamic stress analysis.