Crane rails are vital for efficient operation of large rail-mounted machines. This blog explains how ASPEC‘s expertise helps select rails, joints, and restraints, ensuring reliable systems for equipment like shiploaders, stackers, and reclaimers. We’ll cover design aspects, mounting systems, and supporting heavy loads, all guided by AS1418. Download the article for more.

Crane rail sections are used in a variety of applications in heavy industrial, materials handling, mining and port industries. Large rail mounted machines such as shiploaders, stackers, reclaimers, ship-unloaders and container cranes require reliable rail systems in order to operate effectively.

Design aspects of crane rail selections are covered in Australian Standard AS1418. Rails for bulk materials handling machines are normally continuously welded using the aluminothermic “thermit” welding procedure. The mounting system for the rail is selected to suit the rail, rail loading, the support structure that the rail is mounted on and the rail alignment tolerances.

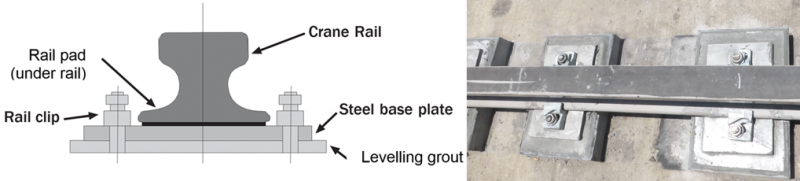

For heavy loads, the rail is generally continuously supported, whereas a discontinuous support can be more economical when the wheel loads are lower. A typical rail mounting system is shown in Figure 1.

Figure 1: Crane Rail Mounting Details

This article provides guidance on the appropriate selection of rails, rail joints and rails restraints for the safe and efficient operation of a crane or machine.

Download the article below, for more information.