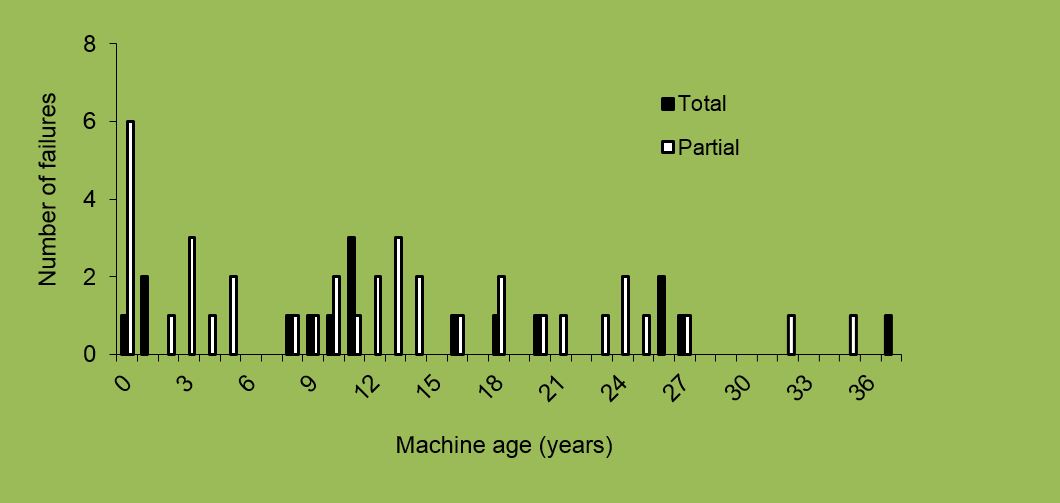

An investigation of the failures of over 60 materials handling machines found that about 10% of failures can be attributed to fatigue failure. In most cases, these failures were unexpected and lead to catastrophic consequences. In this article, the author discusses the process of fatigue damage relating to cranes and materials handling machines.

Fatigue of Bulk Materials Handling Machines

Download

Submit your email address below to access the file download. We won't send you spam or share your email with 3rd parties.

Related articles

Brakes and Wheel Rail Friction

Understanding brakes and wheel rail friction is essential for keeping materials handling machines safe and reliable. This paper looks at the factors that impact friction, like contamination and torque, and offers practical insights for managing performance risks.

Car Dumper Replacement Study

ASPEC was engaged to carry out a combined Order-of-magnitude/Pre-feasibility study for the replacement of a twin cell car dumper. Options considered in the study included combinations of partial and full cell refurbishment, replacement with like-for-like and replacement with upgraded cell designs. The study identified the best option to carry forward.

Aspec Engineering Machine Capability Statement

From initial procurement to replacement or de-commissioning, Aspec Engineering provides a high standard of engineering services across the life cycle of bulk materials handling machines. The latest Machine Capability Statement is now available for download.

Bulk Handling Equipment – Replacement vs Refurbishment

At many existing bulk material handling facilities, equipment such as stackers, reclaimers and ore car dumpers are nearing the end of their design lives. Owners are faced with the decision on whether to refurbish existing or procure replacement machines. ASPEC’s program called FULS (Fatigue Useful Life Simulation) helps determine when to carry out machine replacement or major refurbishment.