Managing industrial assets in Queensland comes with a range of legislative responsibilities that ensure workplace safety and compliance. For asset owners and operators, understanding the Legislative Requirements for Asset Management in Queensland is critical to maintaining operational efficiency while adhering to legal obligations. This blog outlines the essential regulations and practices asset managers need to follow to meet these legislative standards.

Owners and operators of major industrial assets have an obligation to comply with the relevant legislation applicable on their site. In Queensland, for most operating sites the relevant legislation is the Workplace Health and Safety Act 2011. The legislation is uniform over other jurisdictions in Australia. Work Health and Safety Regulation 2011 specifies the way in which a duty under the WHS Act must be performed. Codes of Practice exist which provide practical guidance on how to meet the requirements in the WHS Act and WHS Regulations. Codes of practice are not mandatory and a duty holder may choose some other way to achieve compliance.

The guiding principle of the WHS Act is that people are given the highest level of health and safety protection arising from hazards, so far as is reasonably practicable. This requires a risk management process to understand the risks present in the operation and to eliminate or minimise them.

Under the regulations, the person conducting a business involving the management and control of plant has specific responsibilities for:

- Control of risks arising from installation and commissioning

- Preventing unauthorised alterations to or interference with plant

- Proper use of plant and controls

- Guarding

- Operational controls

- Emergency stops

- Warning devices

- Maintenance and inspection

The Code of Practice for Managing the Risks of Plant in the Workplace refers keeping an up-to-date register of the items of plant requiring regular inspection and maintenance. It is recommended to include information on:

- Allocated responsibilities for people dealing with inspections

- Standards against which plant should be inspected

- Frequency of inspections

- Critical safety instructions to be followed during inspection, for example the isolation procedure

- The procedures for particular types of inspections

- Any variations from normal operation or dangerous occurrences and any trends that may be occurring.

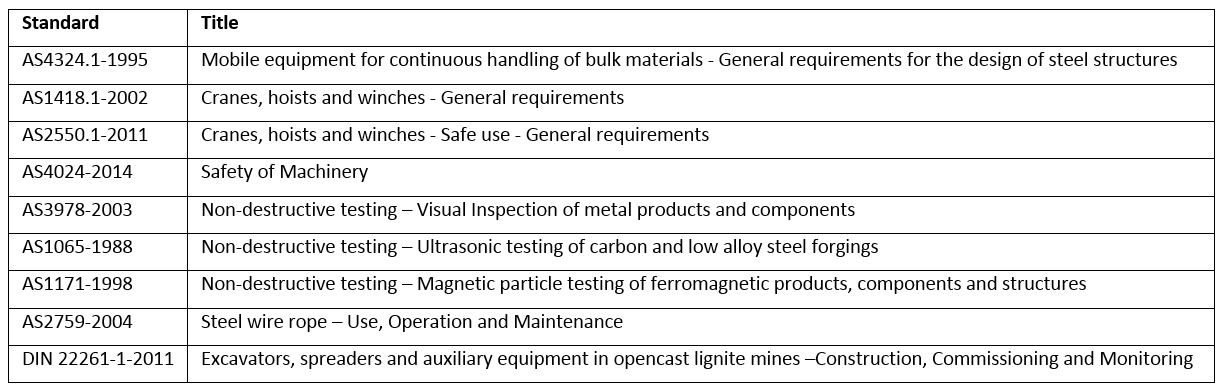

There are a number of Australian and International standards relating to shiploaders, mechanical equipment and asset management of plant assets. Standards are typically not mandatory, and are provided as recommended industry best practice, and a duty holder may choose other methods for achieving compliance (e.g. through testing, other risk mitigating controls etc.). Key reference standards are described as follows (not an exhaustive list of relevant standards):

For more detailed guidance, consult the official WHS Act 2011.