As machinery becomes more complex, regular assessments are essential for maintaining performance and preventing costly failures. ASPEC’s machine health check offers a comprehensive solution, combining advanced data analysis with years of engineering expertise to keep your critical equipment running smoothly.

Control systems on Stackers, Reclaimers and Shiploaders have advanced greatly in recent years and large SCADA* datasets from onboard instrumentation exist. The data can be utilised as part of asset management reviews to understand the structural loadings, fatigue cycles and productivity of the machines. Over the last 5 years, ASPEC has invested in developing advanced algorithms that process raw data from the SCADA* system into engineering information. This allows experienced engineers to perform a ‘Machine Health Check’ that includes the items listed below.

The health check validates if the machine is operating within its safe structural design envelope, and helps stakeholders visualise the performance of the machine. If it is done on a routine basis, the health report can also be used to study the impact of changed operating conditions and for benchmarking across machine fleets.

ASPEC carries out an annual health check of machines at several sites in Queensland, NSW and Western Australia as part of machine risk management audits. ASPEC recommends machine owners should include the machine health check in engineering audits at least every 4 years.

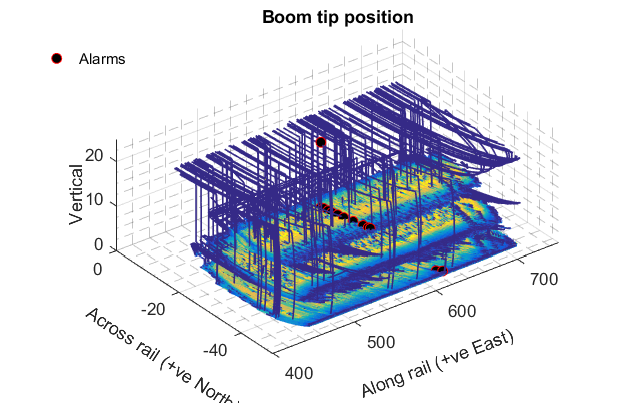

Example of Slew Clutch Alarms Within 3D Stockpile

Based on Boom Tip Position

Sara Vance is a Mechanical Engineer for Aspec Engineering with over 10 years’ experience in technical engineering, construction, minerals, metals and plant design. She is a Chartered

Professional Engineer and has been with Aspec Engineering since 2014.

Mark Biggs is the State Manager for Western Australia and a Senior Mechanical Engineer for Aspec Engineering. He has been with ASPEC since 2004 and is a Chartered

Professional Engineer with 14 years of engineering practice in the mining industry.

*SCADA = Supervisory Control and Data Acquisition