Aspec Engineering undertakes Plant Integrity Reviews (PIRs) for bulk materials handling machines to help owners and operators understand current condition, operational performance and remaining service life.

This article outlines the key components of a PIR, including on-site inspections, Machine Book review, analysis of SCADA data and engineering assessments used to identify defects, assess compliance with AS 4324.1, and inform maintenance, remediation and long-term asset planning decisions.

Jump to: Introduction • On-Site Inspection • Machine Book Review • SCADA Review • Remaining Machine Life • Machine Stability • Conclusion

Introduction

Bulk materials handling machines are subject to significant loads and demanding operating conditions, making stringent maintenance and inspection regimes essential to ensure safe operation throughout their intended design life.

A Plant Integrity Review (PIR) evaluates the machine’s overall health through a comprehensive review of the following:

- The current state of the machine, through on-site inspections.

- The Machine Book contents, including maintenance records, AS4324.1 design documentation, significant loading events and change management records.

- Information from SCADA systems, to compare operating loads to original design loads.

- The remaining machine fatigue life, based on tonnes handled and measured loads.

- The machine stability, based on the latest machine weighing records and measured operating loads.

On-Site Inspection

A PIR includes a comprehensive visual inspection of the machine, including areas not accessible and within the scope of routine structural and mechanical inspections. Inspectors are often required to access confined spaces and use an Elevated Work Platform (EWP) or drone to inspect critical areas not accessible by walkways.

Given the importance of these inspections, the inspector must be suitably qualified and possess extensive knowledge of these machines, including AS4324.1 design loads, structural load paths, and fatigue and strength failure modes.

Each site typically sets its own criteria for acceptable damage, such as corrosion, fatigue cracks and wear. For machines nearing the end of their design life or with known ‘hot-spots’, inspection scopes may specify critical locations for visual or non-destructive testing (NDT).

If damage exceeds the nominated criteria, defects are reported according to client requirements, usually by issuing a summary document that assigns a risk rating, describes the potential failure mode, and recommends monitoring or remedial action. Some examples of defects identified from these inspections are illustrated by Figure 1 and Figure 2.

Low to moderate risk defects, including localised corrosion or minor fatigue cracks, can often be addressed on-site, using an experienced engineer’s advice to repair the defects through blast and paint procedures or weld repairs.

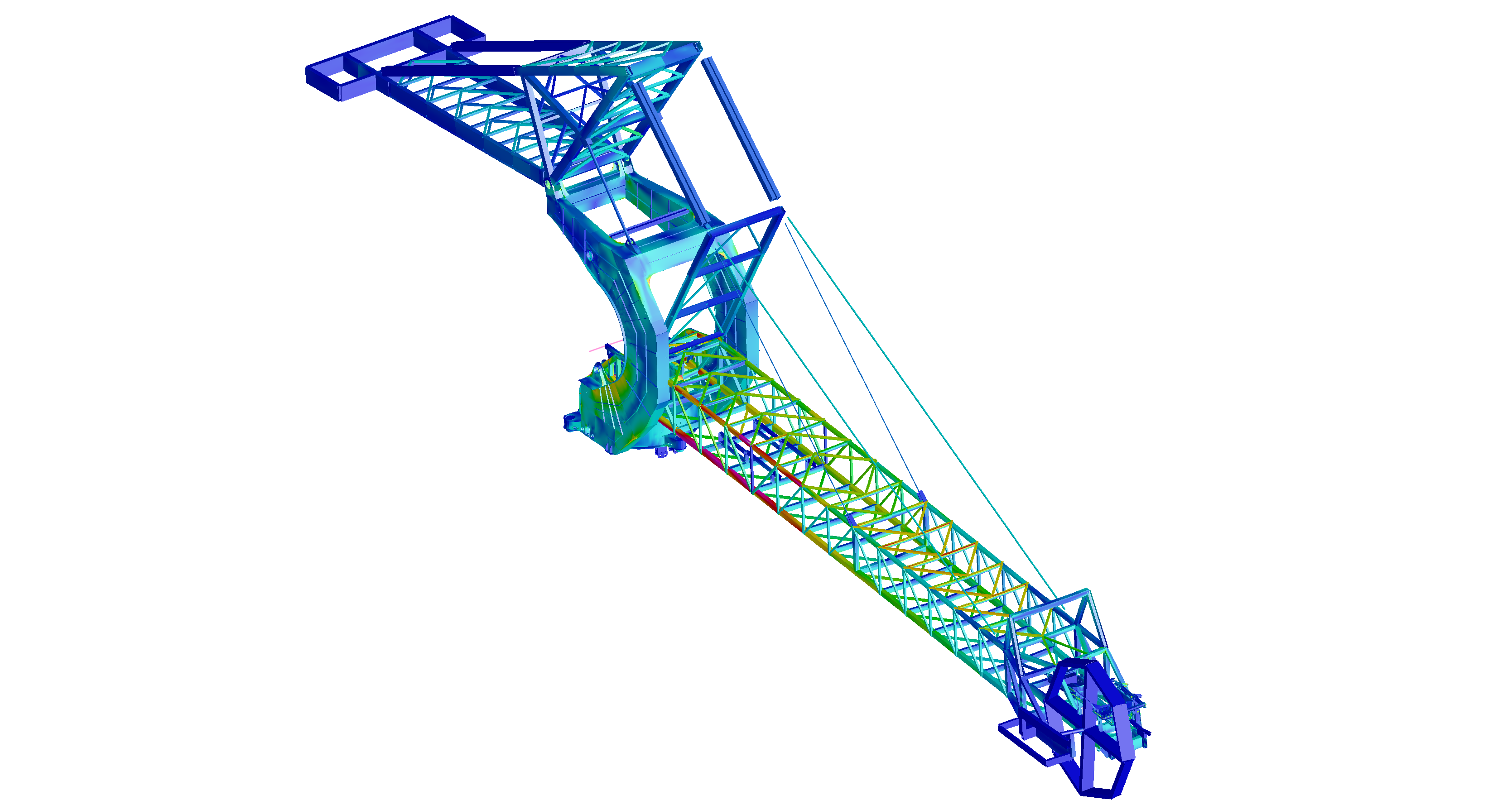

More severe defects, such as extensive fatigue cracking or significant section loss from corrosion, require engineered repair procedures to ensure structural integrity and compliance with AS4324.1 loads and relevant design standards. In these instances, having a finite element analysis (FEA) model of the machine is an invaluable tool for assessing the as built condition, and developing repair solutions that allow continued operation.

Machine Book Review

Australian state government agencies regulating mining safety require comprehensive records for all plant and equipment, including:

- Maintenance and inspection records

- Design and construction documentation

- Documentation of repairs, modifications, and defect notices

- Engineering change records

- Operational and safety documentation

For balanced machines, this information is typically compiled in a “Machine Book”.

A PIR provides an opportunity to conduct an engineering review of the Machine Book to identify missing records, that could indicate inadequate inspection regimes or incomplete design documentation.

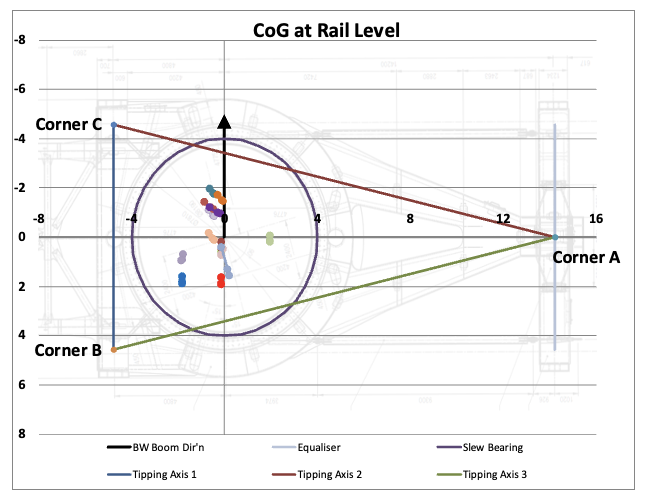

The review should also assess maintenance activities, modifications, and significant events that could have an impact on the machine’s structural integrity. Documenting and evaluating mass changes over the life of the machine is essential in ensuring the machine remains stable.

SCADA Review

As part of the PIR ASPEC analyses SCADA systems, comparing measured operating data to the machine’s original design parameters.

The data reviewed typically includes drive power, throughput, luff position and speed, luff cylinder pressures, long travel position and speed, and slew position and speed. It is often collected over several months.

ASPEC’s in-house tools process this data to generate informative plots for the PIR report, such as:

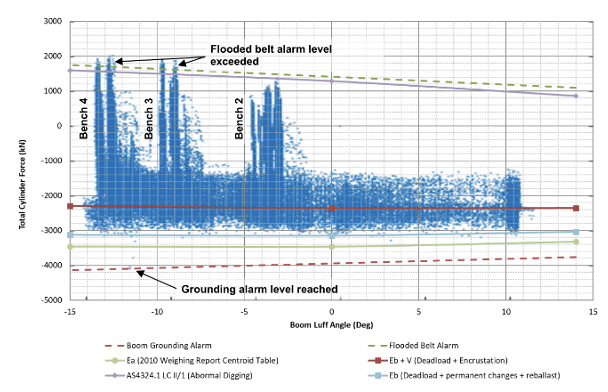

- Luff cylinder or rope loads: Compares the machine’s dead load balance for the range of boom luff angles (or shuttle extension) to the design assumptions, confirming that operating loads remain within the design envelope and protective device settings are functioning as intended (Figure 3).

- Histograms of conveyor live loads and digging loads (for reclaimers): Confirms that operating loads remain below AS4324.1 structural design limits and allows calculation of equivalent fatigue modification factors for remaining life assessments.

- Measured speeds: Confirms long travel, slew, and luff speeds remain below design limits for both operating and non-operating conditions.

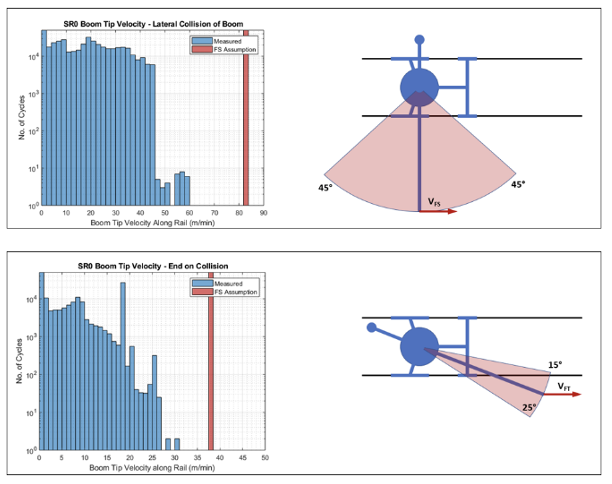

- Boom tip speed: Confirms that the boom tip speed due to combined slew and long travel movements remain below design limits for AS4324.1 boom collision load cases (Figure 4).

Remaining Machine Life

Determining the remaining service life of a machine is a key element of a PIR, as it helps forecast when increased maintenance and eventual replacement will be required.

Due to the nature of loading, the end of operational life for stackers and shiploaders is more likely to come about due to corrosion defects reaching a level where the frequency and magnitude of repairs cause excessive downtime and production loss.

Corrosion can significantly reduce a machine’s structural integrity by causing section loss, particularly in critical load-bearing areas. Over time if the paint protection on the machine is not adequately repaired and maintained, widespread corrosion can lead to the requirement for partial or complete machine replacement.

While reclaimers are also subject to corrosion, their end of life is more commonly driven by an increase in fatigue-related defects as their design life is consumed. The fatigue design life of a machine is reached when the number of fatigue design cycles, or design tonnage, as defined in the original fatigue design load assumptions is consumed.

ASPEC uses in-house tools to calculate equivalent fatigue modification factors from measured loads and cycles, which can be compared to original design values. Fatigue modification factors exceeding AS4324.1 design limits can result in a shorter fatigue life.

ASPEC has extensive experience completing ‘End of Life’ assessments on machines nearing the expiry of their intended design life. As part of these assessments, ASPEC can develop fatigue and corrosion projection curves to indicate when repair costs and unscheduled downtime are likely to exceed operational thresholds, informing when planning for machine replacement should commence.

Machine Stability

A key aspect of a PIR is performing machine stability calculations based on the current balance, which can be established from measured luff cylinder forces and documented mass changes.

Over the life of a machine mechanical and structural modifications, throughput upgrades, or operational changes can alter the machine’s mass balance and reduce stability.

Stability ratio calculations should verify compliance with AS4324.1 requirements for overturning stability. If stability ratios are non-compliant, re-balancing of the machine may be required, which is typically achieved by adjustment of counterweight.

Conclusion

A well-executed Plant Integrity Review provides a clear and practical understanding of a machine’s condition, operating performance, and expected remaining life.

Through a combination of visual inspections, Machine Book review, operational data analysis, and engineering assessments, a PIR enables early identification and remediation of physical and engineering defects, supports informed maintenance and repair decisions, and makes clear recommendations that ensures ongoing compliance with regulatory standards.

Another objective of a PIR is to estimate the remaining service life based on historical operational data and current condition, which provides insight into when costs and unscheduled downtime are expected to increase as the machine approaches the end of its economic life.

Plant Integrity Reviews

Aspec Engineering provides Plant Integrity Reviews to assess machine condition, compliance with AS 4324.1 and remaining service life.

To discuss a Plant Integrity Review for your operation, contact our team.