Value Engineering (VE) isn’t just about trimming costs—it’s about smart investment in a project’s lifecycle. This article sheds light on the Value Engineering process, a critical practice in project management that ASPEC excels at, aiming to deliver the highest value at the lowest cost. We’ll unpack the methodology behind VE, identify where it can go wrong, and provide insights on how to navigate these challenges effectively.

VE is not a design/peer review or a cost-cutting exercise. VE is a creative, organised effort, which analyses the requirements of a project for the purpose of achieving the essential functions at the lowest total costs (capital, staffing, energy, maintenance) over the life of the project. Through a group investigation, using experienced, multi-disciplinary teams, value and economy are improved through the study of alternate design concepts, materials, and methods without compromising the functional and value objectives of the client.

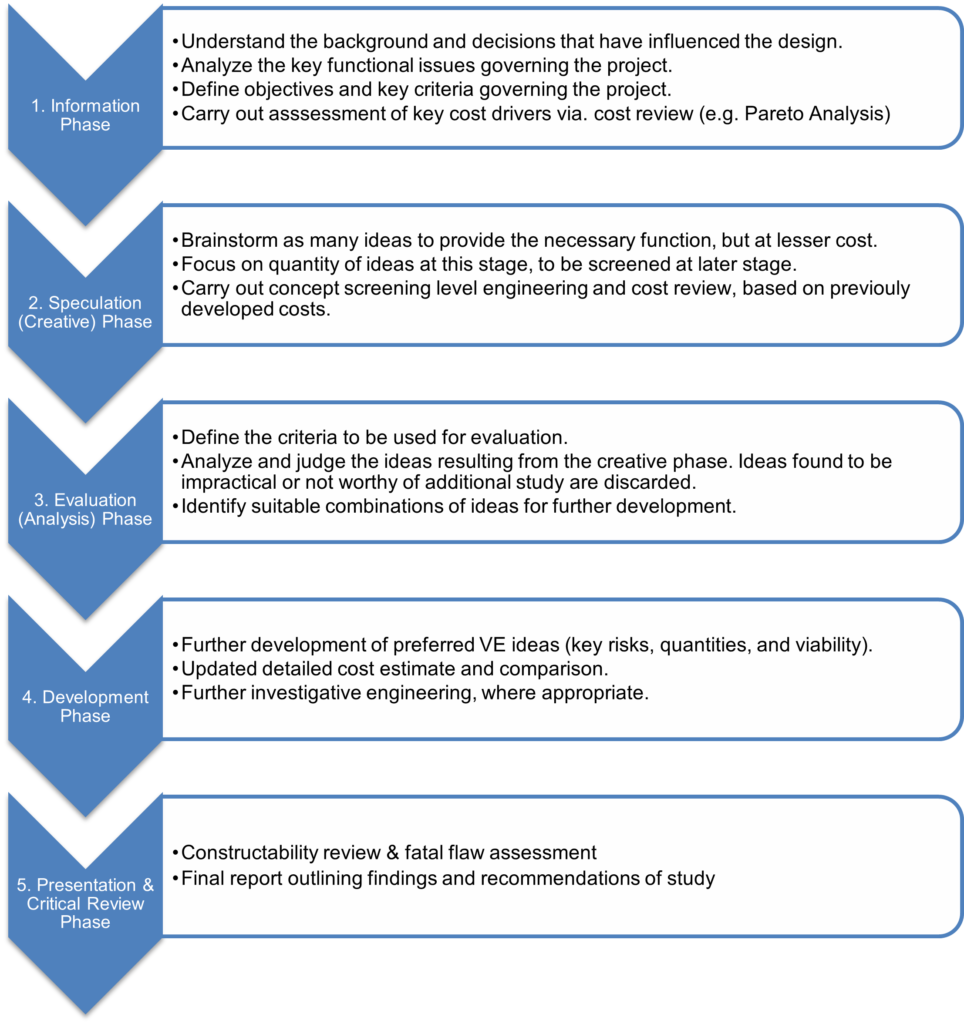

Often the VE Process is broken up into five key phases, with a typical methodology as follows:

Despite the potential benefits of a well-executed VE process, it can sometimes falter due to common pitfalls observed by ASPEC:

- Failure to challenge Assumptions: An essential initial step often overlooked is questioning the core assumptions or requirements guiding the design. Addressing queries such as “Who established and ‘owns’ this requirement?” can unearth hidden assumptions that shape the design trajectory. Challenging or eliminating these foundational assumptions can profoundly reshape the design, unlocking significant value.

- Optimisation Over Deletion: Engineers frequently fall into the trap of optimising design details rather than questioning their necessity. This is a typical bias of engineers and technically minded people – as Elon Musk once said: “Possibly the most common error of a smart Engineer is to optimise a thing that should not exist.”. Before optimising, an important step is to question whether certain parts of the design or process are needed at all, particularly in light of challenged assumptions / requirements. In ASPECs experience, this is where true value can be found – you might be able to reduce costs by 10-20% through optimisation, whereas you can reduce costs by 100% by deletion.

- Overemphasis on Capital Cost: VE processes often overly focus on capital costs and quantities, neglecting other crucial aspects such as project schedule optimisation. Deliberate attention to project timelines, early contractor involvement, and construction methodologies can yield substantial value by minimising schedule duration and operational disruptions. Broader metrics like energy efficiency and long-term operability further contribute to unlocking project value.

- Closed Mindedness: Maintaining an open-minded approach throughout the VE process is paramount. Stagnation occurs when stakeholders become too entrenched in existing designs. Encouraging broad, first-principle thinking devoid of preconceptions allows for the identification of diverse opportunities to enhance project value.

- Team Composition: Effective VE processes demand a diverse team comprising individuals with varied expertise across multiple disciplines, including owners, designers, operators, maintainers, and management. The rigorous critical thinking required to challenge assumptions and deliver value necessitates personnel with profound domain knowledge and familiarity with project requirements. This may require bringing external experts into the process to assist with critical review and fresh ideas.

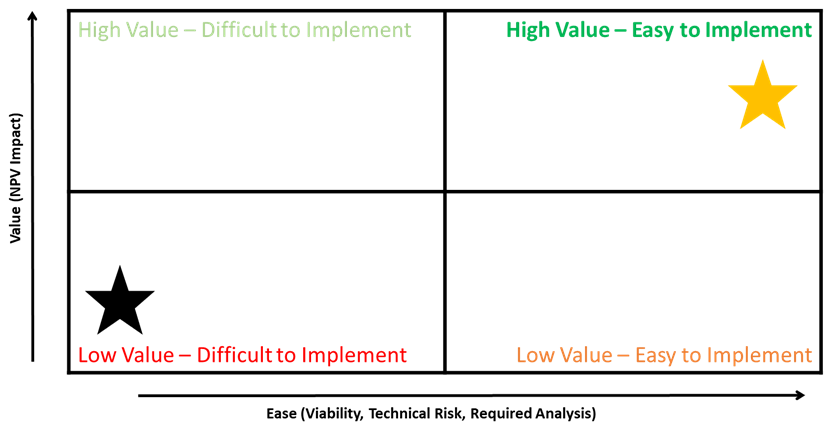

- Pursuing too many opportunities: Following a comprehensive VE assessment, numerous potential opportunities may emerge. However, attempting to pursue all identified ideas can overwhelm project teams, particularly if the process occurs late in the design cycle. ASPEC recommends focusing efforts on high-value, easily implementable opportunities, rather than allocating resources to less impactful or resource-intensive endeavours.

By addressing these common pitfalls, organisations can maximise the effectiveness of their Value Engineering processes, realising substantial value enhancements while ensuring project objectives are met efficiently and economically.

Adam Mayers, is a principal mechanical engineer at ASPEC, with 20 years experience in the heavy industrial and resource sector. Adam is a Chartered Professional Engineer with a PhD in the field of mechanical engineering. Having led projects at most of Australia’s key bulk export ports, he is known for his holistic approach, which integrates diverse engineering disciplines to enhance project value through innovative, sustainable solutions.